Products

Home - Products - EVA shooting monochrome machine

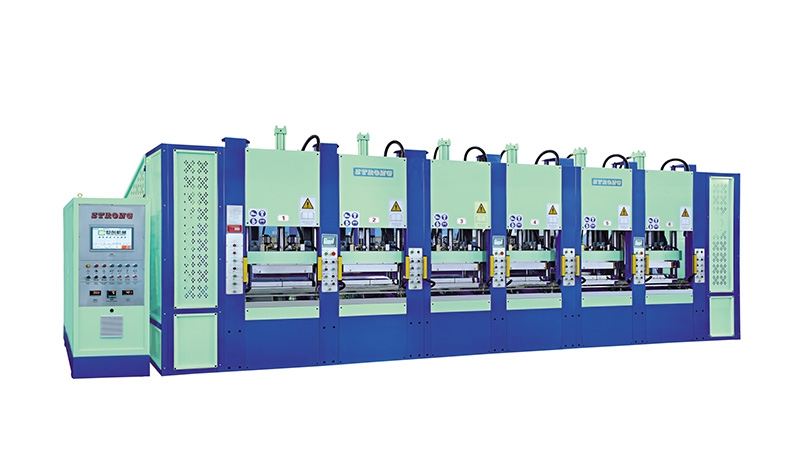

SC-906L2D3 Automatic Foam EVA Injection Moulding Machine

The measuring mechanism utilizes potentiometer detection and coordinates with the operation of PLC to control material quantity precisely. The two injectors move with linear slide and brake motor drive, and its high-speed movement is controlled by inverter; the detent mechanism utilizes rotary encoder to detection place precisely.

2. MOULD CLAMPING SYSTEM:

Two-section quick mould opening and clamping mechanism is equipped with detecting device that has function detection of fully mould clamping.The low operation platform can improve mould-opening stroke and be apply to various kinds of moulds.

3. PC CONTROLLING SYSTEM:

Utilize windows controlling system and human computer system, coordinates with contact screen, we can control material injection rotation speed, injection quantity, injection time, injection temperature, curing time and quantity; the system is easily learned and operated. On the PLC module system, each function and constructure is clear.

4. OIL HYDRAULIC SYSTEM:

Utilized servo oil hydraulic system, improve system safety, stability, decrease noise to enhance production efficiency. Coordinating with computer control system, we can control pressure and flow rate of different sections precisely.

5. ENERGY-CONSERVATION DESIGN

No need water circulation for mould stations and utilize efficient heating insulator.

6. SERVO ENERGY-CONSERVATION SYSTEM

Selecting servo energy conservation system can save about 30% energy.

| Model | Unit | SC-904D3 | SC-906L2D3 | SC-908L2D3 |

| Raw materials | EVA | EVA | EVA | |

| Work stations | 站/stations | 4 | 6 | 8 |

| Mould clamping force | ton | 315 | 315 | 315 |

| Mould size | mm | 360x750x2 | 360x750x2 | 360x750x2 |

| Mould opening stroke | mm | 450 | 450 | 450 |

| Die height | mm | 300 | 300 | 300 |

| Screw diameter | mm | Φ75/ Φ80 | Φ75/ Φ80 | Φ75/ Φ80 |

| Max injection capacity | g | 1400/2500 | 1400/2500 | 1400/2500 |

| Injection pressure | kg/cm² | 1000 | 1000 | 1000 |

| Injection speed | cm/sec | 10 | 10 | 10 |

| Screw rotating speed | r.p.m | 0-110 | 0-110 | 0-110 |

| Temperature control | 段/stations | 5 | 5 | 5 |

| Heating power of barrel | kw | 19 | 19 | 19 |

| Heating power of mould | kw | 77 | 115 | 154 |

| Total electricity | kw | 165 | 205 | 245 |

| Oil tank capacity | l | 1000 | 1000 | 1000 |

| Machine size (L*W*H) | mm | 7000x5600x2900 | 9200x5600x2900 | 11400x5600x2900 |

| Machine weight | kg | 31500 | 42000 | 55500 |

| The above technical datas are just for reference,in case of any change without any prior notices. | ||||

If you are interested in the above products, please fill out the form below and the relevant personnel will contact you promptly. (Note: Please fill in your information correctly)